| Supervisor: Gary S. SchajerRenewable Resources Laboratory Dept. Mechanical Engineering University of British Columbia Vancouver BC, Canada V6T 1Z4 |

|

|

Background

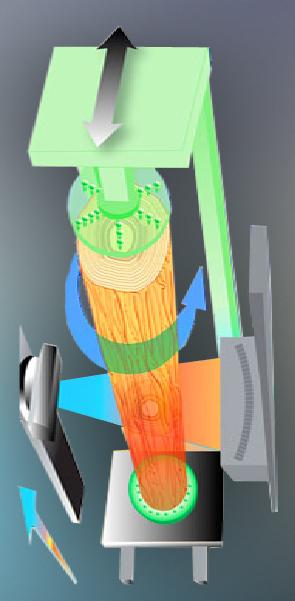

This project is designed to assess the feasibility and potential effectiveness of using coarse resolution Computed Tomography (CT) scanning for in-line log grading. The application is of interest because it has the potential to separate high-value logs suitable for producing lumber and veneer from much lower value logs only suitable for making composite panels and pulp chips. At present, log grading is done by human visual inspection, and is very inconsistent. Medical CT scanners have reached a high degree of sophistication, with commensurate high complexity and cost. For an industrial CT system, the design and scale of the device have to be kept within a practical range to achieve appropriate durability, cost and speed. Lower spatial resolution requirements allow the design of a much simpler, lower cost, and computationally less intensive CT scanner for log grading applications. Initial work has demonstrated that coarse-resolution CT measurements in logs can successfully identify interior features such as heartwood and sapwood, and the presence of knots and decay. The key feature for success is an a-priori knowledge of the expected structure of logs. This knowledge allows pragmatic selection of data analysis algorithms to achieve very efficient and effective results. In contrast, medical CT scanners cannot assume any known structure because they must accept a wide range of measurement sources, i.e., human patients.

Computed Tomography (CT) works by X-raying the object in several directions to obtain a set of radiographs (X-ray images). By mathematically manipulating the set of radiographs, it is possible to compute the interior structure of the measured object in three-dimensions. In medical applications, very fine spatial resolution is required. Thus, a rotating sensor must measure in approximately a thousand directions to provide sufficient data. Such fine spatial resolution is both unnecessary and undesirable for industrial log scanning. Scanning and computation time must be reduced to the few seconds available while processing each log in a sawmill.

Commercial X-ray log scanners are available with up to three views. They are used for radiographic imaging to detect foreign objects such as metal fragments, not for CT work. The greatly reduced spatial resolution required for logs offers the possibility that some useful results can be achieved with a small number of X-ray views, perhaps just the three available from a commercial log scanner. In this project, three-view and other CT scanner configurations are being explored.

Significance

- The development of a practical low-resolution CT log scanner will allow high-quality material in sawmills to be identified and directed to high-value uses.

- Use of a-priori information will greatly simplify scanner design and reduce costs.

- Compact algorithms will enable real-time identification of the interior features of logs.